Why EOT Crane Need Predictive Maintenance? Prevent Major Breakdowns

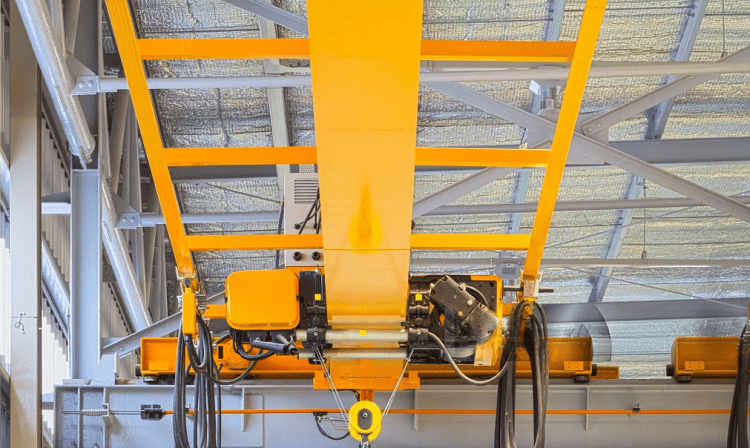

EOT (Electric Overhead Travelling) crane maintenance is not merely a normal operation; it is a need in businesses where efficiency and safety are of the utmost importance. This inventive method helps to see possible problems; before they become serious and cutting downtime. Thus, your machine gets better performance from applying predictive maintenance.

Predictive maintenance enables with cutting-edge technologies, including IoT sensors and data analytics that makes guarantee your cranes run as efficiently. Then, as possible while reducing the need for expensive repairs and unplanned breakdowns.

Here, you will learn more about top reasons to apply predictive maintenance for EOT cranes and how it supports operations, keep reading.

EOT Crane Need Predictive Maintenance: Top Reasons

A series of detrimental effects that impact productivity, safety, and overall operating expenses can result from neglecting EOT crane alignment services. Here’s a closer look at why routine maintenance is so important:

Safety Risks

Safety of nearby operators and employees is seriously threatened by a broken crane. Heavy loads are handled by EOT cranes, and any malfunction in one of its parts—the hoist, trolley, or bridge. So, these could cause weights to fall, causing serious injury or even death. Frequent maintenance reduces the chance of accidents and makes the workplace safer.

Downtime

Unexpected malfunctions might cause major downtime by stopping your entire operation. In addition to interfering with your operations, this results in significant expenses because of missed production. By identifying and resolving possible problems; before they become serious ones. Thus, scheduled maintenance helps keep your crane in good working order and prevents expensive disruptions to your business.

Decreased Productivity

Reduced output and inefficient operations might result from even small problems with your EOT crane. For example, a misaligned track or a worn-out engine can cause the crane to operate more slowly. So, this will impact the load handling speed and accuracy.

Frequent maintenance and inspections maintain your crane operating at peak performance. Along with, this makes guarantee that it makes a valuable contribution to your production processes.

Higher Repair Expenses

If neglected, minor concerns can grow into bigger ones that need costly repairs. For instance, neglecting a little hydraulic leak over time might harm important parts and necessitate expensive replacements. By identifying these problems early on, routine maintenance helps keep them from becoming major financial burdens.

Extended Equipment Lifespan

Maintaining your EOT crane on a regular basis not only guarantees its immediate operation, but also increases its longevity. Equipment that is properly maintained lasts longer, functions more dependably, and sustains less wear and tear. Long-term, this translates into fewer replacements and a higher return on investment.

Observance of Industry Rules

Any business must follow industry standards and safety rules. By ensuring that your equipment conforms to the applicable safety norms and regulations, routine maintenance of EOT cranes helps you avoid legal responsibilities and possible fines.

Improved Dependability and Performance

EOT cranes that receive regular maintenance operate dependably and consistently, increasing your operations’ overall efficiency. You can make sure the crane runs smoothly, safely handles loads, and reduces the chance of unplanned failures by doing routine inspections and maintenance. Meeting project deadlines and sustaining consistent production rates depend heavily on this dependability.

Enhanced Self-Belief of Operators

When using well-maintained equipment, operators are more certain and productive. They can concentrate on their duties without worrying about possible problems. This is because; they know the crane is in good working order. Better performance, increased morale, and a more productive staff are the results of this.

Professional Maintenance Services

Hiring our professional Laser Alignment Services ensures thorough inspections and expert handling of repairs. Laser Tech Solution offers precise maintenance services that keep your EOT cranes in better condition with safety and reliability.