Turbines, Stacker & Windmill Alignment Services make sure that the proper alignment of the machinery in the power, industrial and renewable energy sectors. By use of the modern laser and optical tools; these services correct the misalignments in entire machinery.

Turbine alignment services consist of accurate positioning of the spinning components to make certain operation in the faultless coordination. Advanced tools such as laser alignment systems, optical tooling and computerized diagnostic equipment are using in this process.

The main focus of this is to eliminate the misalignment, which happened due to the thermal expansion, foundation shifts, or an improper installation. These type of services are mainly using during the turbine installation or after the huge overhauls.

Turbines are the crucial components that use in the different industries mainly in power generation, oil and gas and the manufacturing. Either it’s a steam, gas or hydro turbine. Their production is heavily based on the accurate misalignment; if the shafts, bearings or the couplings.

An uneven alignment in the turbines can results in an excessive wear, maximize the vibration, energy losing. To mark these problems, Turbine Alignment Services provides the specialized solutions that make sure the precise location and effectiveness operations of these vital equipments.

This alignment service is important in the various sectors especially, where turbines consider as main part of the operations:

The stacker reclaimers are the necessary part of the pieces of machinery. They are available in bulk to manage the production like mining, energy generation, cement and port operations. The huge equipments are applied to stack and reclaim bulk materials involves the coal, iron core, and lime stones and other aggregates.

Large size, the flawless operation, and slight misalignment can results in the crucial problems includes the component wear and unrealistic downtime.

These are the specialized services for the procedures maintenance to make certain accuracy in alignment of these equipments. It helps in the increasing and optimizing the performance and expanding their operational longevity.

A stalker reclaimer is a combination of two functions in a single machine: stacking the huge materials into the stockpiles and the reclaiming them when required. Essential components use in stacker reclaimer, such as boom, bucket wheel, slew bearing and conveyor systems; they run along with rails. These features are aligned proper to avoid the structural stress and uneven wear and machine failures.

Ensures the proper alignment lowers the unplanned downtime and increase the equipment availability

This services is important for maintain the performance and the life of the large materials handling systems. Through modern alignment technologies and the well skilled technicians, the production ensures the smooth, safe and the cost effective operations.

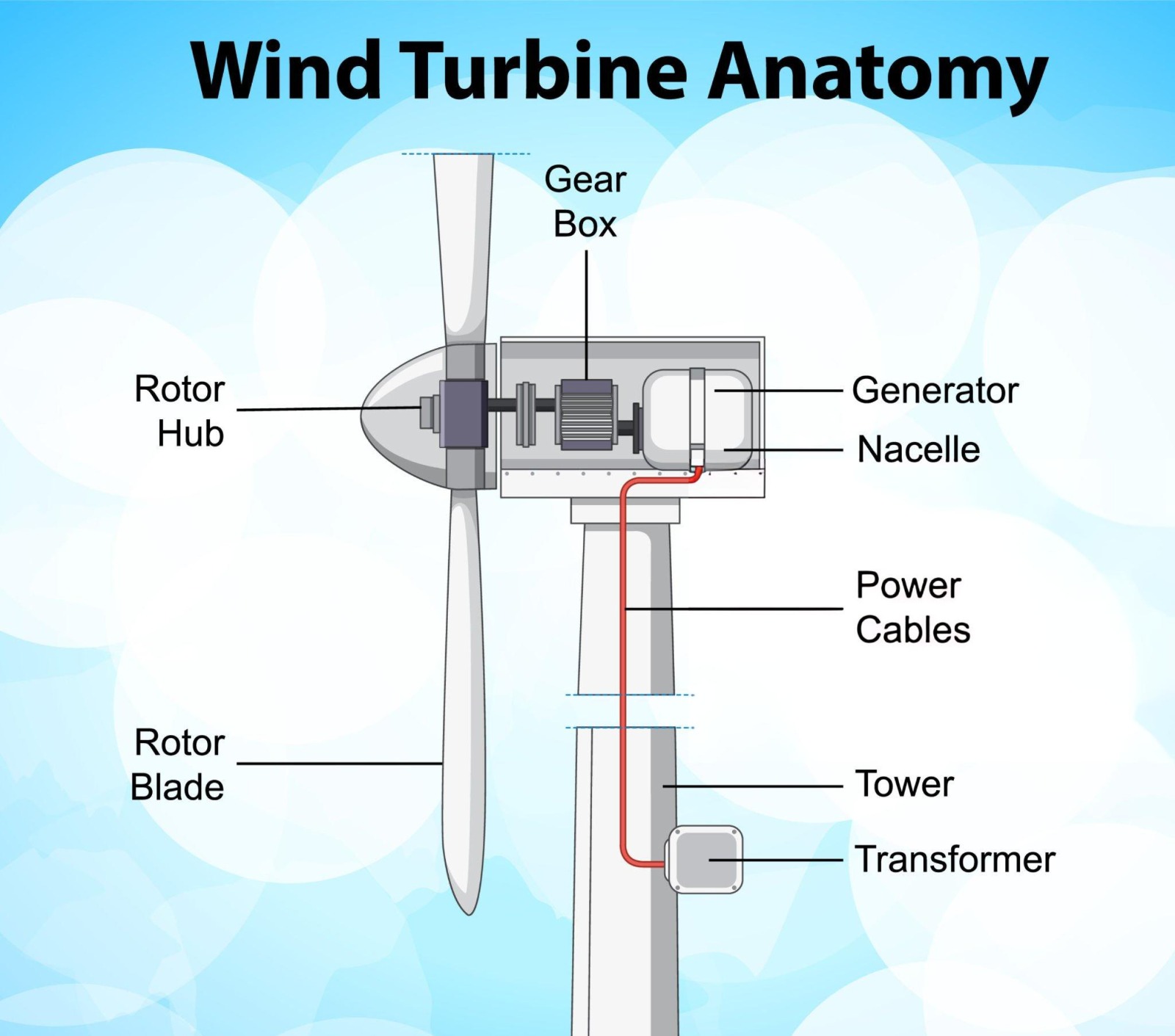

Windmills means the advanced wind turbines play a vital role in the global shift toward the renewable energy. The structures harness the wind energy to produce electricity effectively and eco friendly. The accuracy of any equipment depends on the correct alignment of the major key components.

So, Windmill Laser Alignment Services are necessary for the maintenance of the optimal operations, reducing downtime and expanding the longevity of the wind turbine systems.

The wind turbines contain the various key components which include the rotor hub, main shaft and the gearbox generator. All components must be work in accuracy coordination to make sure that the energy is increased and the stress is decreased. The factors like thermal expansion, foundation movement, vibration and operational wear can results to misalignment.

Misalignment in wind turbines can result in:

At the final, windmill alignment services are a vital aspect of the wind turbine for maintenance and performance optimization. Always make sure to operate in accuracy harmony which helps to lowers the operational cost, improves the efficiency and expands the lifespan of the turbine. Using of regular and precise laser alignments services is necessary for sustaining the reliability and gaining of wind energy assets.