The Role of Predictive Maintenance in CNC Machine

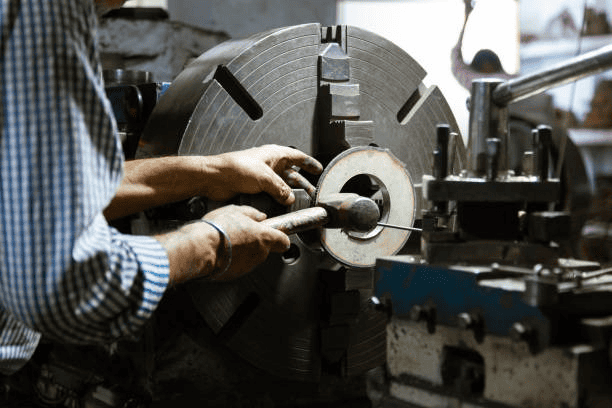

In this world of accurate production, CNC that stands for Computer Numerical Control) machines are the main component of productivity for its precision and consistency. Whatever either like a mechanical system also they are dependent on the wear and tear. For this reason; it play vital role of predictive maintenance in CNC machine to stay get better result in their productivity.

The maintenance of these machines is comparatively high which includes fixing the problems at the time of occurrence, avoiding or scheduling the maintenance at the continuous intervals. With the modern technology, data analytics and the machine learning has become more efficient strategy that has appeared for the predictive maintenance.

The PdM which means the Predictive Maintenance make the use of this in the real time data and the past trends to anticipate when the features of the machinery is about to fail. These machines not only avoid the costly breakdown but also enhance and increase the machine lifespan, production efficiency and the safety.

Why Do We Need CNC Machine Maintenance?

No proper CNC machines maintenance, the production may experience the non expected downtime and the late productions. Schedule the inspections and the potential preventive methods are the two main methods to keep these machines operates in a good condition.

Most of the users are dependent on the specialized maintenance personnel to maintain the machines and prevent any unpredicted downtime. Near about 80% of the maintenance favors the preventive measures.

From Downtime to Uptime: The CNC Maintenance Shift

These machines are generally harder and complex system that made from the spindles, ball screws, servo motors, coolant systems and the various different electronic components. Earlier, manufactures are getting to depend on the two types of the maintenance approaches:

Reactive Maintenance: Stop until a machine fails before fixing the issue.

Preventive Maintenance: Conducting the daily examining at the fixed duration.

These two approaches have few limitations.

The reactive maintenance results in an unplanned downtime and some serious repairs.

Preventive maintenance is better than the reactive and can be inefficient. This includes the part replacements that are in a good situation, or skipping the wear on the components that lose before the routine checks.

Get CNC Machine Alignment Services Price!

Initiate the Smarter and the safer alternatives by analyzing the data to direct the decisions.

How Predictive Maintenance Works in CNC Machines?

CNC machines includes the observing the different parameters in the present time using IOT sensors and modern software. Here are few ways how it actually works:

The sensors collect the data on the vibration, temperature, lubrication levels, power consumption, spindle load and the cycle times.

Modern algorithms inspect the collected data and recognize the trends or anomalies that may show the signs of the potential failures.

The system discovers the early signs of wear or malfunction. Thus, it notifies for maintenance before the problem becomes vital.

Maintenance teams get the detailed diagnostics which permit them to plan the repairs with not interrupting the production schedules.

As soon as the vibration sensors find the maximized level in a spindle which might shows the bearing wear. This system alerts the maintenance teams to schedule the services and avoid the unplanned loss in between the production run.

Advantages of Routine Maintenance for CNC Machine Tools

The recommended maintenance process for CNC machinery helps to make sure that they get the better quality control and expands the life of the machine. This is specifically necessary for the companies that depend heavily on their CNC machine for the production. Here are the few main types that can be using for the regular maintenance for benefit:

Essential machine repairs can consume more precious time. Continuous maintenance process schedule for time that is reliable to minimize the unexpected downtime later.

Carefully inspections and timely replacing the parts can particularly expands the machine’s longevity.

This machine tool is important in financial investment; proper care will make sure that it stays in the working condition.

Continuous machine maintenance helps to lowers the scrap rates and better overall product quality.

Conclusion: The Future of CNC Maintenance Is Predictive

Now these days, Predictive maintenance does not come in buzzword; but it is a competitive edge. It helps to stay away by minimizing the downtime, better performance and money savings. CNC machines are developed so it should be cared. So, we deal in many Laser Alignment Services, including CNC Machine Alignment, and other Geometrical Alignment Services.