What Is Predictive Maintenance for Wind Turbines? Full Guide

Predictive Maintenance allows developing and the implementation methods for recognizing any failures of recurring system and reduces failure costs through early warning signs. This maintenance enables a wind farm to minimize the failure costs and delivers the value to the customer. So, predictive maintenance gets combining the machine learning algorithms and the analysis of the historical data.

Importance of Predictive Maintenance in Wind Energy

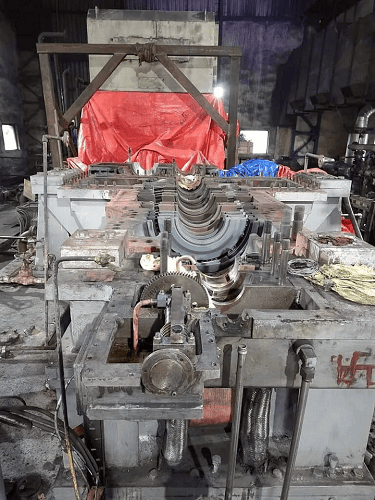

Wind turbines come in the list of enlarges machines with involving many moving parts like gearboxes, blades, and yaw systems. These kinds of parts are subject to the particular wear and tear from the different environmental conditions such as wind speed fluctuations, and change in temperature.

Downtime due to the components failure can cause the repair costs and lost in energy generation.

So, predictive maintenance helps to mitigate the problems by regularly observing the health of turbine components and the failures predictions before happening them. This maintenance is going to perform only when it is essential.

Thus, it helps to lower the downtime and preventing catastrophic breakdown.

Benefits of Predictive Maintenance for Wind Turbines

Through forecasting failures, you can schedule for maintenance between the low wind periods and grouping with other activities. Along with, it also helps to reducing the operational disruption and cutting of downtime.

Prevent the unwanted maintenance and avoiding the major breakdowns lowers the overall maintenance expenses.

Detection of the issues allows the small repairs which avoid the further destruction. So, it lets the extending the longevity of the components.

Regular operations with fewer failures make sure that the turbines produce the highest energy.

Lesser emergency repairs minimize the requirements for the risky maintenance in the worst conditions mainly the offshore.

Key Technologies Used

The following are the key technologies using in predictive maintenance for wind turbines:

Across the turbines, sensors and IOT devices are pre installed to examine the variables like oil quality, vibration, rotor speed, noise and temperature. The sensors that produce vibrations are important to locate the timely symptoms of the wear in bearings and the gearboxes.

SCADA Systems stand for ‘Supervisory Control And Data Acquisition’ gather the present data that is being operated from the turbines. The analysis and detection of faults rely on this foundational data.

Examination of the sensor data to discover the anomalies and use the turbine features condition. A slighter vibration change in the patterns specifies the evolving problems in the rotational parts.

Test the historical and present time data to recognize the patterns and see when the features are about to fail. These machine learning models and AI algorithms can instruct to identify the rapid warnings that the human users operators may miss.

Manage the huge amount of data from the trains of the wind turbines need the robust cloud infrastructure. Tools for large data reserve the process and monitor the information throughout the different multiple turbines to enhance prediction precision.

Deploying the predictive maintenance comes up with challenges. The initial cost of sensors installation and the evolving the breakdown capabilities can be high. Make sure the data precision and conducting with the false optimistic in the models that need the regular refinement of model and professional oversight.

Another difficulty is data Integration. Merge the SCADA Data with the CMS and other examination sources to get interoperability. Cyber security is becoming more critical and vital by maximizing the digitalization which forms the turbines that are susceptible to cyber threats.

Future of Predictive Maintenance for Wind Turbines

Predictive maintenance plays a vital role in maximizing the sustainability and efficiency of the wind in the farms. Through the Advancements in AI, machine learning and the Internet of Technology has the capability for more sophisticated and the precision noticing systems that will develop.

The ways to transform the wind turbine blade healthy is done by the predictive maintenance. It handles carefully and provides the unparalleled advantages in effectiveness, reliability and the initial cost savings.

The solutions that are innovative mostly empower the sustainable resources to increase the possible of wind turbines with reduction in the environment. Implementing this technology make sure that a renewable and effective future to produce the wind energy.

Final Remarks: Predictive Maintenance in Wind Turbines

This maintenance is using to represent a particular advancement in the operations and handling of wind turbines. By fetching the data and using the advance technologies, it allows the operators to anticipate the failures and proper optimization to handle the maintenance schedules.

The starting implementation of this can be costly and complex but it is effective too. It provide the long term advantages in the minimize downtime, reduction in cost, and safety improvement.

These all combine to form a compelling strategy to form the future of wind energy. These technologies regularly develop, so it is more likely to make a best practice in the sustainable energy sector.

So, our team also deals in many Laser Alignment Services, including Windmill Laser Alignment Services, EOT Crane Alignment, and other Geometrical Alignment Services.