Laser Alignment for Hydraulic Lifter Level Control in Lucknow

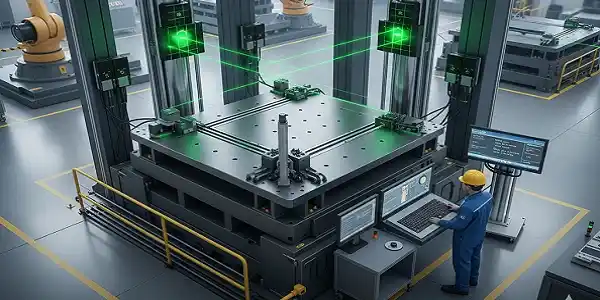

As Lucknow’s automotive and industrial sectors are advancing, the need for precision engineering is also increasing. Workshops and service centers are using modern technology to make tools more reliable and improve engine efficiency. Laser alignment technique is a modern solution for controlling the level of hydraulic lifter level control, providing precise operation, minimal interruption, and durable mechanical performance.

The Importance of Hydraulic Lifter Level Control

Hydraulic lifters play important role in internal combustion engines and hydraulic actuation systems. It is maintain proper valve clearance, make sure smooth camshaft operation and contribute directly to engine efficiency.

Grab This: Shaft Alignment Service in Delhi

The hydraulic lifters level control are not properly aligned, then it to be increase noise, less fuel efficiency, cause valve timing issues, and parts wearing out quickly. In a Lucknow where all kinds of vehicles are constantly in use, maintaining the engine’s optimal performance is important.

The correct level of the hydraulic lifter level control balanced mechanical motion and reduces stress on energy and components. But, laser based alignment system proves to be more precise and effective compared to traditional methods.

Benefits of Laser-Based Hydraulic Lifter Alignment

Enhanced Accuracy

As we know a laser system capable of measuring with micrometer-level accuracy makes hydraulic lifter calibration perfect. And, improve valve timing allowing the engine to run smoothly.

Faster Service Time

Traditional alignment takes more time. But, Laser-based alignment system completes maintenance quickly by providing real-time data and increases workshop performance.

Improved Engine Performance

As we know proper hydraulic lifter level control helps improve engine performance. If lifters are perfectly aligned, then the engine control more efficiently, less vibration, and consumes fuel more properly.

Reduced Wear and Tear

Let us discuss correct Hydraulic lifter alignment evenly distributed mechanical load reduces pressure on the camshaft, valves, and pushrods. So, this allows the engine to last longer and reduces maintenance costs.

Reliable Non-Contact Inspection

Through the Non-contact measurement technology, the engine can be safely inspected without contact, which is beneficial for both new and old types of engines.

Growing Demand in Lucknow’s Automotive Sector

In Lucknow, there is a continuous increase in the number of vehicles, transportation services, and industrial activities. Along with improvements in service levels, workshops are investing in modern diagnostic tools, and adopting Laser alignment technique based hydraulic lifter alignment technology keeps them ahead in the competition.

Grab This: Shaft Alignment Service in Kolkata

Now we discuss vehicle owners are focusing on proper engine performance improvement, leading to an increased demand for modern solutions like laser-based alignment. Industrial establishments in Lucknow are also adopting this technology to save costs and ensure the longevity of machinery.

Future Scope of Laser Alignment in Lucknow

With automation and digital monitoring, laser-based alignment system is now becoming standard in premium automotive workshops and industrial plants.

Grab This: Shaft Alignment Service in Lucknow

With the growing demand for smart diagnostics and predictive maintenance, precise hydraulic lifter level control will play a significant role in enhancing operational efficiency.

The use of Non-contact measurement technology makes maintenance safer, more efficient, and precise, in line with modern engineering standards in Lucknow’s developing industrial sector.

At The Final

As we know that laser alignment technology for hydraulic lifter level control is a significant advancement in automotive and industrial maintenance in Lucknow.

The precise alignment, reliable measurement, and effective calibration maintain engine performance over time, and with increasing awareness, laser-based systems will redefine precision engineering standards in the field.