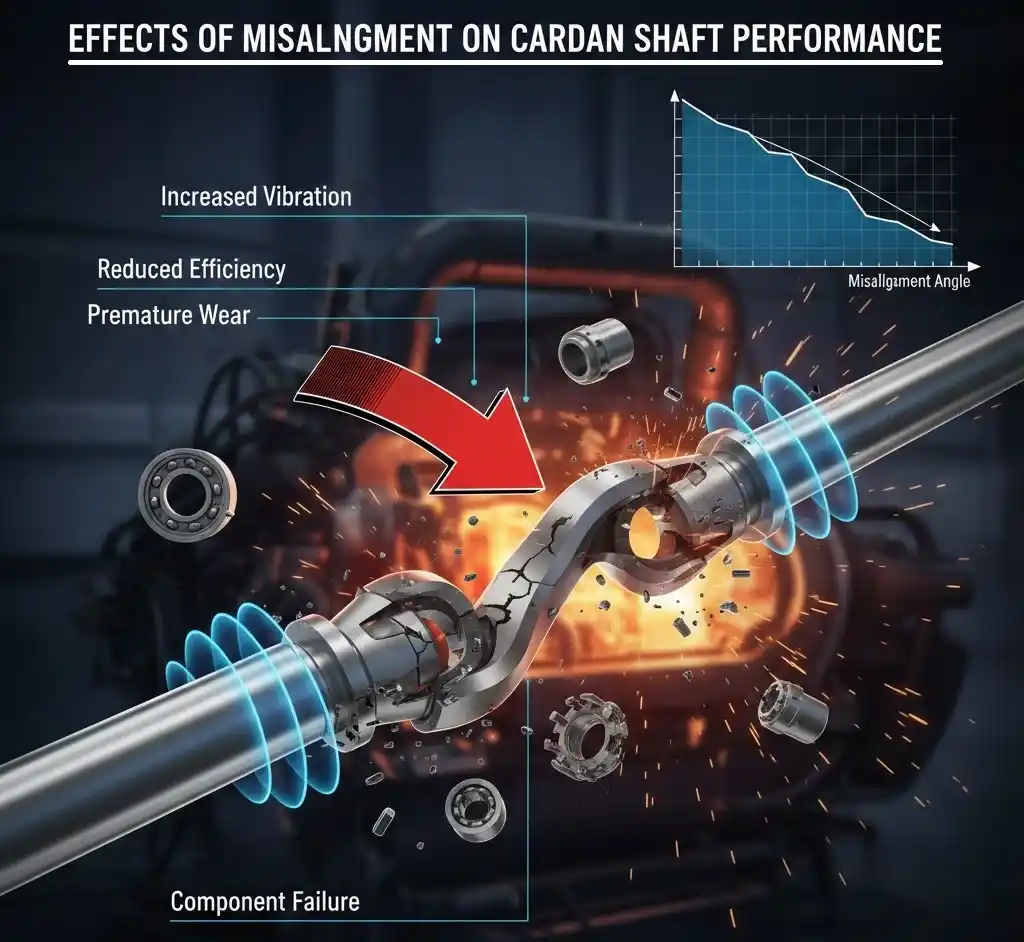

Effects of Misalignment on Cardan Shaft Performance

Now, lets us discuss cardan shafts that commonly known as universal joint shafts or propeller shafts, and also called universal joint shafts or propeller shafts. That is important parts that help transfer power in machines. You are finding them in cars, industrial machines, ships, and heavy equipment. They connect two shafts that may not be perfectly aligned and allow them to rotate together.

While these shafts are handle some angle changes, if they are Cardan shaft alignment not aligned properly, that are reduce performance, waste energy, and shorten their life. That’s why it’s important to know the effects of shaft misalignment to save machines running smoothly and save maintenance costs.

Types of Cardan Shaft Misalignment

Misalignment happens when the operate shaft and the driven shaft are not in the right position. The main types are angular misalignment (offset) parallel misalignment, and axial displacement. Universal joints are handling small angle changes.

But, too much misalignment causes uneven rotation and extra stress. Its builds machines less stable and reduce their life.

Increased Vibration and Noise

One of the first signs that a Cardan shaft is misaligned is too much vibration and noise. When shafts are at the wrong angle, universal joints rotate unevenly, creating the whole system to shake.

Grab This: Shaft Alignment Service in Kolkata

This is damage bearings, seals, and couplings, and less machine accuracy. In cars and heavy machines, misaligned shafts many time generated shuddering, rattling, or rumbling sounds.

Reduced Efficiency and Energy Loss

Proper shaft alignment makes sure smooth transfer of power and better efficiency. If the shafts are misaligned, friction grow at the joints, brings energy loss and higher operating temperatures. This less overall performance and that increase fuel or electricity usage. In heavy industrial machines, even small alignment mistakes are lead to high long term costs.

Accelerated Wear and Premature Failure

Misalignment puts broken stress on the universal joints, bearings, seals, and shafts, its builds them wear out faster. They are collapse lubrication and cause surface damage like brinelling and corrosion, shortening the life of parts.

If ignored, misalignment even leads to total Cardan shaft failure, creating machine downtime, safety hazards, and expensive repairs. That’s why daily alignment checks are very important to save the drivetrain reliable.

Impact on Fatigue Life and System Dynamics

From a structural point of view, misaligned Cardan shafts face extra bending and repeated stress, which shortens their fatigue life. At high speeds, these forces get stronger, causing more vibration and faster cracks in yokes and shaft tubes. Studies show that properly aligned shafts spread the load evenly, lees vibration, and last longer between maintenance.

Best Practices for Cardan Shaft Alignment

To less the problems caused by shaft misalignment, maintenance teams must be follow best practices like laser shaft alignment, using dial indicators measurements, and vibration analysis.

Grab This: Shaft Alignment Service in Delhi

It’s also important to check universal joint phasing, maintain proper operating angles, and inspect bearings and couplings regularly. Shafts must be realigned after moving equipment, foundation shifts, or when parts expand due to heat.

Final Remarks

Misalignment greatly affects the performance of Cardan shafts, generated vibration, power loss, faster wear, and small equipment life. Even between universal joints its handle few angles, exceeding the recommended limits are less drivetrain reliability.

By using proper Laser Alignment Services and regular maintenance, organizations that improve efficiency, less downtime, and make machines last longer.