Turbines, whether used in power plants, refineries, or industrial applications, require precise shaft and component alignment to maintain efficiency and avoid catastrophic failures. Even the slightest misalignment can lead to excessive vibrations, overheating, and structural damage.

Using state-of-the-art laser alignment technology, we provide:

Shaft-to-shaft alignment – Ensuring precise connection between turbine components.

Bearing and coupling alignment – Reducing friction and extending component life.

Thermal growth compensation – Accounting for expansion during operation.

Vibration analysis and correction – Minimizing wear and energy loss.

Stacker reclaimers operate in mines, ports, and bulk material handling facilities, requiring perfect alignment to ensure smooth and efficient movement. Misalignment can cause structural stress, reduced efficiency, and increased maintenance costs.

We provide precision laser alignment to ensure:

Boom and counterweight balance – Preventing structural instability.

Rail and wheel alignment – Reducing stress on components.

Slew bearing and gearbox alignment – Ensuring smooth rotation and efficiency.

Structural and mechanical analysis – Detecting potential alignment issues early.

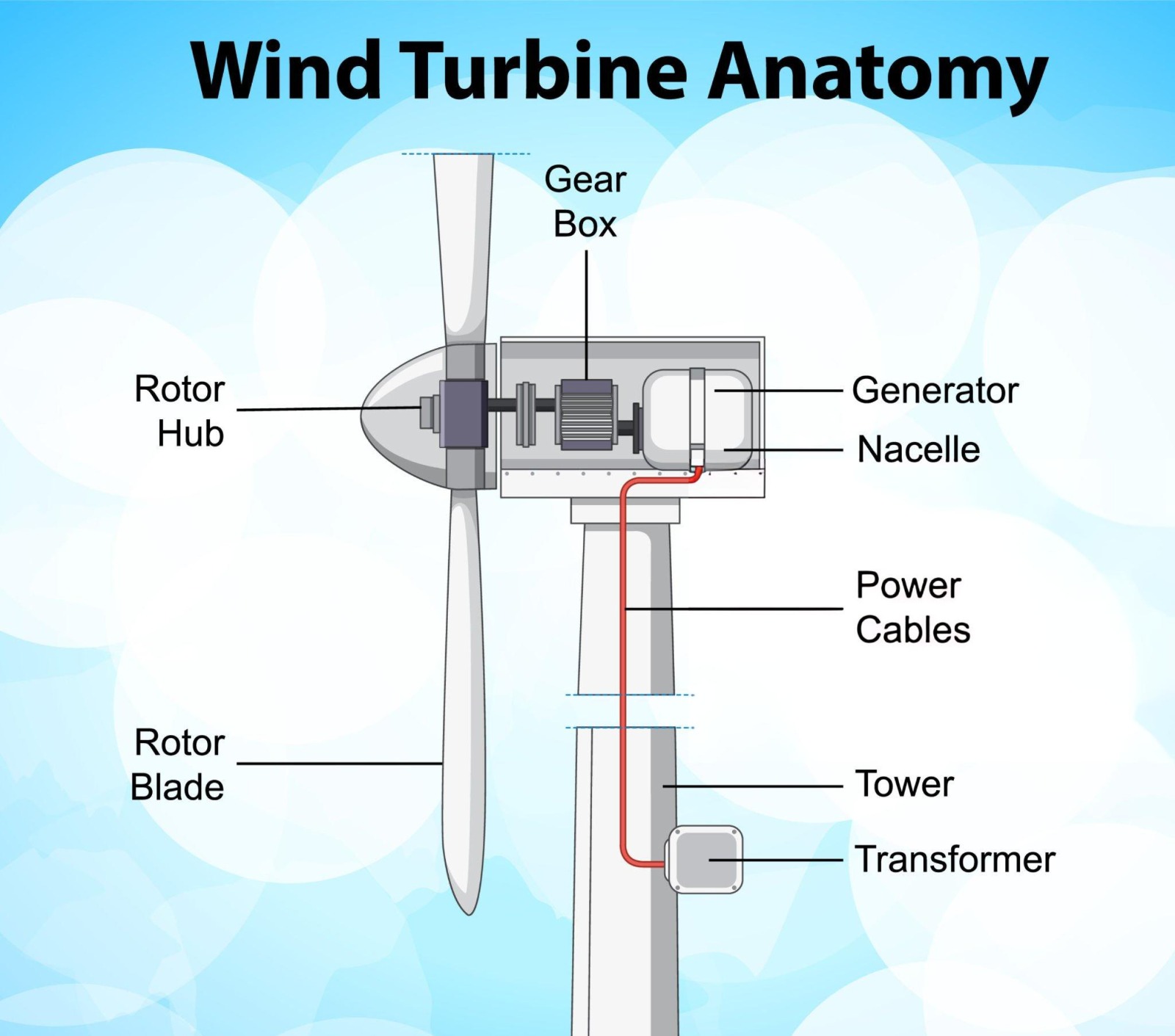

Wind turbines require precise rotor and gearbox alignment to optimize energy generation and reduce stress on components. Poor alignment can lead to excessive loads on the blades, bearings, and tower structure, increasing maintenance costs and reducing energy output.

We use advanced laser alignment techniques to ensure:

Rotor and shaft alignment – Improving energy efficiency and reducing wear.

Gearbox and generator alignment – Enhancing power transmission accuracy.

Blade pitch and balance optimization – Minimizing stress on the turbine structure.

Vibration and load analysis – Identifying and correcting inefficiencies.

Proper alignment requires precise adjustments, and precut shims play a crucial role in achieving accurate alignment. We provide high-quality precut shims that offer:

Using precut shims in alignment procedures helps enhance machine efficiency, reduces vibration, and prolongs equipment lifespan.

Our Shims made of selected materials suitable for use as shims. Thickness of all shims is controlled to be as close as specified; with high hardness and springness to reduce any possibilities of thickness change in use.

If you are experiencing issues with your machinery due to misalignment, contact us today for professional horizontal and vertical shaft alignment services. Our experts will ensure that your equipment runs smoothly, efficiently, and with minimal downtime.

Call us today or request a consultation!