In many places, you need to ensure that the surfaces are perfectly straight, e. g., when using a lathe, CNC, etc.

It is desirable that the tool moves during a straight path to obtain the perfect cylinder and it is possible only when the guiding guideways are themselves straight Line or plane is the basic unit of measurement for most methods of measurement. The standard of straightness in precise engineering is represented by a ruler. According to Bryan’s Principle, a straightness measuring device should be aligned with the functional point at where straightness is to be determined. If this is often difficult, either the slideways that transfer the measurement must not move at an angle or angular motion data should be used to calculate the result of the offset.

A line is considered straight if the variation of the distance between any two points on the line from two planes perpendicular to the line and parallel to the line itself remains within the required tolerance limit. The reference planes are so chosen that their intersection lies parallel to the line joining two points on the road to be measured.

Therefore, the two points are close to the ends of the lengths to be measured. The straightness tolerance is defined because the maximum allowable deviation from the reference line joining the two ends of the road is to be inspected.

It is the standard procedure to state the range of measurements, i.e., to check the length; and the position of tolerance about the reference line. output must be a single paragraph. Most often, the parts at the very edge of the ends, which usually have local errors of no major importance, may be neglected or ignored.

Straightness is measured every day in several industries. as an example, for instance, members, rollers; pipes, the machine ends; machine runners, and conveyor belts. Straightness measurements are taken for bearing positions, for example, in diesel engines. Straightness is usually an important requirement for a machine to operate correctly and/or produce fault-free components.

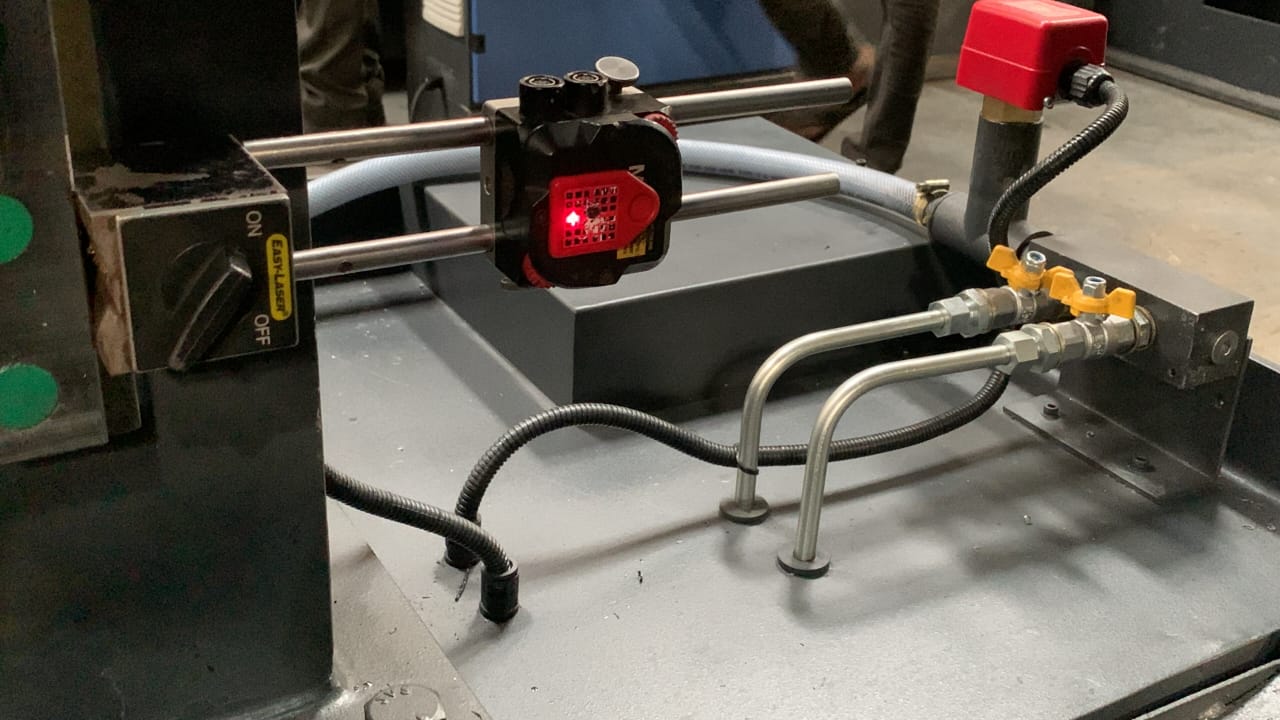

The basic principle of Straightness Activity is that each activity value shows the position of the detector relative to the sunlight beam. the sunlight beam could also be visualized as a very, very, long, fully straight, weightless ruler. First, the beam must be roughly aligned with the activity.

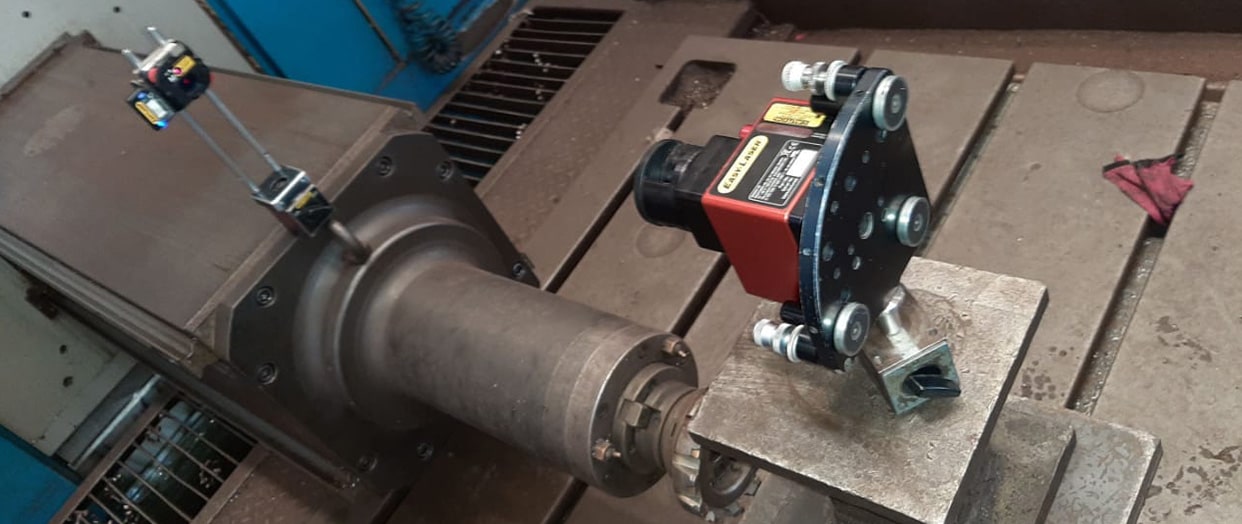

With our laser alignment tool, you’ll be able to check the straightness of any round profile inline and with just one measuring routine. The measuring frame is designed to be installed directly into your existing line and contains at least three pairs of measuring sensors the thing rolls through a measurement system within an inspection process and is scanned The measurement result shows how far off the straightness of a line is from the straightness of a reference line. You may optionally set additional parameters like the length (or diameter) and ovality of the object.

Squareness alignment ensures that perpendicular components maintain a 90-degree angle, which is crucial for proper machining and assembly processes. Any deviation affects precision and product quality.

We offer expert alignment services using advanced tools, including:

Squareness verification – Ensuring correct perpendicularity between components.

Column and gantry alignment – Checking and correcting vertical and horizontal planes.

Frame and base plate assessment – Ensuring overall machine stability.

Roll parallelism is essential for industries using rollers, such as printing, paper, textile, and steel manufacturing. Proper alignment ensures uniform material processing and prevents uneven wear.

Our specialized alignment solutions include:

Precision measurement of roll positioning – Detecting and correcting deviations.

Roller axis alignment – Ensuring uniform material distribution.

Thermal expansion analysis – Compensating for heat-related distortions.

Proper alignment requires precise adjustments, and precut shims play a crucial role in achieving accurate alignment. We provide high-quality precut shims that offer:

Using precut shims in alignment procedures helps enhance machine efficiency, reduces vibration, and prolongs equipment lifespan.

Our Shims made of selected materials suitable for use as shims. Thickness of all shims is controlled to be as close as specified; with high hardness and springness to reduce any possibilities of thickness change in use.

If you are experiencing issues with your machinery due to misalignment, contact us today for professional horizontal and vertical shaft alignment services. Our experts will ensure that your equipment runs smoothly, efficiently, and with minimal downtime.

Call us today or request a consultation!